Name Marcus O’Mahony, Student # 10133364

What sustainability issues will arise from the large scale adoption of electric cars?

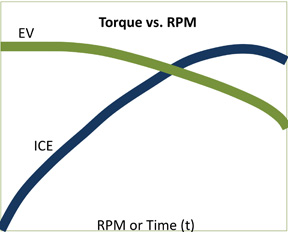

First off I am a huge fan of electric vehicles, or EVs for short, if for no other reason than the driving experience that these vehicles promise. As I’ve already mentioned in a previous post, the electric motor is an ideal motive source in particular due to its torque characteristics whereby virtually the full torque produced by the motor is available immediately from zero revs. This is dramatically different to an internal combustion engine, particularly the petrol engine, which doesn’t produce its maximum torque until typically 2500 revs or higher (depending on the application that the engine is used in). The manner in which the torque is delivered by an internal combustion engine also fairs worse than that of an electric motor, as torque from an internal combustion engine builds to a peak. Many manufacturers try to design internal combustion engines with as flat a torque curve as possible to minimise the effect of this peak. Diesel engines in this regard fair better than petrol engines. It’s predominantly why diesel engines, especially modern diesel engines are much more relaxing to drive as the driver perceives more “power” being available at lower revs. This in turn, I think it’s fair to say tends to lead to a higher level driver satisfaction with their car. A simplified torque graph for EVs and for an internal combustion engine might look like this:

Ok, so even without a detailed scientific analysis of the psychology of the driver, I think it’s fair to say that torque is good given the feeling of power that it instils and therefore electric motors are an ideal motive power source. Added to this are the green credentials of EVs and the hybrid EVs which are currently the most readily available form of EVs. We all think of EVs as being very environmentally friendly, the standard electrical motor in a Tesla delivers a typical efficiency of 88% or 90%; 80% at peak power, whereas an internal combustion engine is only roughly 20% efficient. They burn no hydro-carbons when you get in to them to drive them. And of course they are quiet and therefore won’t disturb the peaceful idyllic nature of the leafy suburbs where we all live. In the face of mounting oil prices and dwindling oil reserves, the inescapable truth of global climate change and the fact that we value our personal transportation highly, EVs would appear to be the answer. What could possibly be wrong with something that you simply plug in at night and drive quietly the following day to work. Range should not be a problem as the infrastructure will be put in place so that there are charging points handily located at the street side. For sure further development is still required in terms of battery technology and motor technology, but isn’t that one of the best things about EVs – they’re new, they’re at a very early stage in their development, especially when we consider the 100 plus years of development that has already gone in to internal combustion engined cars, so the sky is the limit in terms of what EVs will develop in to.

However there are many downsides to EVs. The first and most obvious issue with EVs is the generation of electricity to charge them. Current EVs such as the E-Mini or the Nissan Leaf use anywhere between 22 kWh to 34kwh respectively of electricity per 100 miles (depending on how you drive etc.). With specialised charging station efficiencies of between 80% to 90%, to refill your batteries you will require 24.5 to 37.5 kWh of electricity. Users will typically recharge their cars when they come home from work, having possibly used generic charging points at street level during their working day to top up their batteries (depending on the cost). This means that the typical spike in electricity usage which occurs each evening, roughly between 17:00 and 19:00, as people come home and cook dinner, wash clothes etc. may either be exacerbated or the period may be extended, depending on whether a user plugs their car in immediately or after they’ve had their dinner, or a second spike would be created if they plug in their cars when they go to bed at night. Either way the extra electricity usage will further strain already overstressed electricity grids and also happen at a time of day when certain renewable electricity generation options, such as solar power, may not be available as it will be dark. But what about the availability of wind power? This is unreliable as it is dependent on the wind blowing and it has also been shown that even if we covered our country in wind farms and other renewable sources of electricity generation, which isn’t practical, renewable energy sources simply won’t be able to produce enough electricity to meet current demand, not to mention the added demand created by electric vehicles needing to be recharged.

From an article by Prof. Chris Rhodes – “the majority of electricity in the U.K. is generated using power stations fired by coal (28%) and gas (45%)……..To decarbonise the national grid would require another 30 – 40 GW of green generating power, or “the equivalent of a hundred large offshore wind-farms,” according to the chief economist of the Committee on Climate Change (CCC). These would need to be large indeed. Assuming a rated capacity per turbine of 5 MW, and a capacity factor (actual output) of 30%, we have 1.5 MW for each. Thus we need around 20,000 – 27,000 turbines to produce 30 – 40 GW of power. So that means 100 wind-farms with 200 – 270 turbines each. If one turbine per day were manufactured, no mean feat given present manufacturing capacity, the process would take 55 – 74 years to complete, with the installation of them as a separate effort……..there is the further question of whether there will be sufficient quantities of rare earth elements (REEs) available on the world markets to make the turbine magnets which need about one tonne of neodymium per 4 MW of rated capacity” and also “It is claimed in a Royal Academy of Engineering (RAE) report on electric cars that they are in any case cleaner because 80 – 90% of the energy put into them in terms of electricity is recovered in terms of useful power at the wheels, to be compared with 20 – 30% in a conventional oil-powered car. Well, that sounds good, but the reality is that only about one third of the energy in the coal or gas actually ends-up as electricity because of the Second Law of Thermodynamics and the Carnot Cycle limit – the other two thirds being thrown away as heat. Thus the electric car is harvesting in terms of well-to-wheel miles only about 27% of the original fossil fuel energy, so not that much better than the standard car running on petrol or diesel. The difference is merely whether about the same quantity of waste heat energy is thrown away at source or in the vehicle”. Aside from the rare earth elements mentioned, Prof. Rhodes hasn’t even touched on the subject of the rapidly dwindling supplies of oil and the CO2 emissions caused by the internal combustion engine burning petrol or the impact of building of these wind farms in terms of embodied energy and CO2. As of May 2010 Ireland has an enough installed renewable generation to meet approximately 14% of electricity demand with a target of generating 40% of electricity demand from renewable sources by 2020. Many other countries around the world are also currently heavily dependent on electricity generation from non renewable sources which mean that far from being the zero emission vehicles that we would all like them to be, EVs are simply shifting their carbon footprint when in use from point of use, as happens with an internal combustion engine vehicle, to point of generation.

The Physics Factbook states that in 1997 there was 600,000,000 motor vehicles in the world with a projected vehicle population of 1,200,000,000 by 2030. In 2007, 10 years later, the number of vehicles on the road had already reached 806,000,000. These figures include cars and light trucks. The Organisation Internationale des Constructeurs d’Automobiles (OICA) provisional production statistics for 2010 indicate that approximately 77,609,901 vehicles will have been produced in that year. The Energy Information Administration’s (EIA) 2007 Annual Energy Review (AER) estimates the actual number of EVs on the road in America in 2004 as 49,536 and a preliminary estimated 2006 number of 53,526. Growth in EV sales is expected to be approx. 39%. Germany’s National Electric Mobility Platform (NEMP) is a government initiative to develop Germany into a leading market, with about 1 million electric vehicles on its streets by 2020. The Irish Government has set a target of 10% for all vehicles on Irish roads to be electric by 2020. Virtually all governments are offering considerable financial incentives toward the purchase of an EV. If we assume this is successful and there is a resultant, modest, 10% market penetration worldwide for EVs within the near future, then we can assume that there will be at least 7.7 million EVs built per year. If all of these had a charging requirement daily of 30 kWh of electricity, then there is an additional demand of 231,000,000 kWh per day of electricity! How is this going to be generated? Even if it can be generated there is the problem of distributing it to where it is required. Existing grid networks are typically overloaded as it is. From Wikipedia – “In the UK , while National Grid’s high-voltage electricity transmission system can currently manage the demand of 1 million electric cars, Steve Holliday (CEO National Grid PLC) said, “penetration up and above that becomes a real issue. Local distribution networks in cities like London may struggle to balance their grids if drivers choose to all plug in their cars at the same time.””. So in addition to the problem associated with building a frankly ridiculous amount of wind turbines, there is also a need to upgrade the electrical grids in many countries also, not least our own. Again this will incur a not insignificant embodied energy and CO2 debt which must be paid off in order to make the impact of these changes neutral.

If we assume that there is a requirement in the near future for 7.7 million EVs to be produced annually, then there is a significant market opportunity here for all major carmakers who are currently in a race to be the first to market an all-electric car and to claim the mantle as the world’s greenest automaker. There are some interesting facets to the production of cars and EVs with regards to CO2 emissions and also the raw materials that are used in their construction. Previous estimates of the CO2 footprint of the production of a car range from 12% of its total life cycle CO2 footprint to 28% in a more recent Toyota study from 2004. Some unsubstantiated figures being published in the media at present can put this figure up as high as 50% for modern, electronic laden cars and hybrid EVs. The production of a Toyota Prius requires the equivalent of 113,000,000 BTUs of energy. A gallon of petrol contains approximately 113,000 BTUs of energy, meaning that a Prius will need to travel approximately 46,000 miles before it has recouped the energy required to produce it in the first place.

How often do manufacturers introduce new models? The Toyota Corolla and their second generation Prius for example were on a six year product life cycle, Honda’s Civic was on a 4 year product life cycle, although this has been increased to 5 years. Typically there is a mid life refresh in all of these products anywhere between 2 to 4 years in to their product cycle depending on how successful their sales are. Interestingly the product life cycle of the first generation Prius was only 3 years, reflecting the newness of the concept and the rapid development of the technology used thereby justifying a second generation Prius after only 3 years. At the other end of the spectrum, consumer goods such as an iPhone have a product life cycle of only one year before a new one is introduced and you’re subjected to media and advertising hype telling you why the new model is so much better than last year’s model – kind of makes you feel like a berk for having last year’s model and makes you instantly want to rush out and buy this new and improved model. With traditional cars having product life cycles of 5 years approximately, but modern day electronic goods having product life cycles ranging from one year for consumer electronics to 2 – 3 years for some white goods are EVs in danger of becoming something that will be frequently replaced as they are simply glorified white goods now? Because the product is new and there is a significant amount of technological advancement happening it allows marketing departments free reign to constantly hype the next product re-spin and drive sales to an unsustainable level, treating the EV as nothing more than the next killer app. We also need to consider the fragility of modern vehicles due to their reliance on electronics. Anecdotal evidence would suggest that current vehicles with their extensive integrated electronic control systems are not as robust as older generation cars. Of course in older cars there is less to go wrong. The added complexity introduced by the electronic systems has introduced additional opportunity for failure in the product. Cost cutting is surely partially to blame for any increased fragility in modern cars. Even though people allegedly demand more and more features (marketing led), there is also pressure to deliver these features cheaper. Inevitably the quality of the product suffers. Combined with planned obsolescence or at the very least functional obsolescence, this means that people are holding on to their cars for shorter periods currently before replacing them. Marketing plays its role in this as well. Bringing pressure to bear on consumers through constant advertising, touting the next advancement that you simply must have in order to save the planet. Electric vehicles require much less service and maintenance than internal combustion engine vehicles. They do not require routine oil changes. They do not have any tailpipe emissions and therefore do not require any exhaust system work. They do not require replacement spark plugs, pistons, hoses or belts. The conventional parts of the car—including the brakes, body work and any interior and HVAC work—can be performed by any qualified automotive technician or local provider. We are all familiar with the story of the washing machine breaking down and being charged an exorbitant service charge just for a technician to have a look at it only to be told that the repair of it will actually cost almost as much as a shiny new machine. Further evidence of functional or planned obsolescence. So what about EVs – they’re predominantly an electrical item also, will they become worthless or uneconomical to repair once a minor obsolete or major electronic component fails. If they are uneconomical to repair what will happen to them? They’ll be scrapped of course, however we’ve seen enough evidence of the recycling process that so much of our electronics undergo – being shipped to a developing nation for people to break them down in the most unhealthy and environmentally unacceptable manner in order to recover some of the valuable rare earth elements that have gone in to their manufacture. Can we honestly say that making and then eventually scrapping and recycling, through dubious methods, to partially recover valuable but toxic elements is sustainable?

Rare earth elements are used extensively in the construction of modern cars and especially hybrid and EVs. And it’s becoming quite an issue at the moment as over 90% of the world’s rare earth element sources are controlled by China, who have recently placed significant export restrictions on these materials. Rare earth elements aren’t actually rare, they are however very difficult to extract. Hybrid cars can contain well in excess of 11.4 kg of rare earth elements. The Prius uses large amounts of rare earth materials in its electric motors and batteries. Each battery uses 15 kg of lanthanum and the electric motor uses 1 kg of neodymium. Two other rare earth elements, terbium and dysprosium, are also added to the alloy to preserve neodymium’s magnetic properties at high temperatures. The generally accepted figure for modern internal combustion engine cars is approximately 4.5 kg. Older cars would have significantly less again. Now if we take our notional 7.7 million EVs, which because of their all electric nature, as opposed to a hybrid design like the Prius, will require up to twice as much rare earth elements as even the Prius, then the probable minimum global requirement for rare earth elements for the production of EVs could be somewhere in the region of 175,000,000 kg. The mining or extraction of these rare earth elements is difficult leading to undesirable extraction processes both in human and environmental terms.

And as with any scarce resource that is attracting large prices and currently maintaining a meteoric rise in price level, inevitably securing sufficient supplies will lead to conflict. It has been well document in the case of oil and with current restrictions in place it is conceivable that conflict will also occur with regards to the distribution of rare earth elements. We can only view this as being utterly unsustainable.

Finally as a general commentary on personal transport, the vast majority of journeys undertaken in a car are single occupancy journeys. You have one vehicle capable of carrying 5 or more adults transporting only one. Even if a minimum or three people shared one vehicle, it would remove the requirement for 2 in 3 vehicles to be on the road. The introduction and wide scale adoption of EVs will do nothing to change this trend or make personal transportation more sustainable. In fact it may introduce a whole range of new problems associated with the sustainability of personal transport. Ideally we should share our vehicles or if being the sole occupant of your vehicle is of great importance to you, we should be using the opportunity arising out of the introduction of EVs to also dramatically change our preconceived notions of personal transport and downsize our vehicles. If a vehicle is used only by one person, then it should only be big enough to comfortably transport one person, as opposed to five people. Downsizing our vehicles will make them lighter and hence easier to propel, consuming less energy in the process and will they will obviously consume fewer resources in their manufacture.

So what you may ask is the answer? Biofuels perhaps – provided you don’t go down the route that America did and produce their ethanol from corn, thereby causing widespread price inflation of corn on the world markets and making it too expensive for people who need to buy it as their food. Brazil is a good example of how Biofuels such as ethanol can be produced without impacting the human food chain. Personally I’d rather continue driving an older car, which is less dependent on the all pervasive electronics and the associated rare earth elements that have been consumed in their production, and that in an ideal situation has been sensibly converted to run on biofuels such as bio-ethanol.

Don’t buy that new car. Buy a well maintained used car instead and continue to maintain it properly – Use it up, wear it out, make it do, or do without. That idea may not be palatable for many people but consider the fact that the more you use an older car the more likely you are to pay off the carbon and energy debt incurred in its manufacture. If it can be converted to run on a sustainable fuel, all the better. Alternatively we can invest in extensive and reliable public transport systems. Why move one individual at a time in a single vehicle when instead you can move many people together.

Buy a bike and cycle or combine cycling with an extensive and reliable public transport network. It’s better for you and for the environment.

Or perhaps the solution can be found in the movies. Enter Doc Brown and his Mr. Fusion Home Energy Reactor from the film Back to the Future.

Only in Hollywood I’m afraid.

PDF of the above:

I think the only way to produce sustainable, renewable, and high output energy is through nuclear power. I’m talking about Gen IV reactors here, not what currently exists or what is currently being built. Once we’ve built those reactors, then we can easily meet and exceed energy requirements for a lot less cost and impact.